- ISONITE

- (Salt Bath Nitriding)

- It is suitable for the Soft Nitriding Treatment of all kinds of steel and can be treated quickly.

- Compound layer generated by ISONITE process improves abrasion resistance, corrosion resistance, heat resistance and fatigue strength.

- Deformation and distortion is minimized since process temperature is below A1 transformation point.

- ISONITE can be applied to various ferrous metals such as carbon steel, cast iron and stainless steel.

- It improves adhesion and bonding strength.

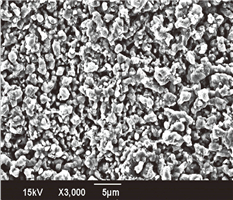

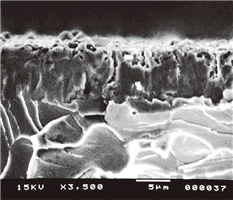

Cross Section Model

- A compound layer of columnar crystals is formed on the surface of the material processed with ISONITE. The compound layer improves oil conformability and abrasion resistance in oil. It is also effective for improving adhesion of paint and resin. The diffusion layer formed under the compound layer improves the fatigue strength of the material.

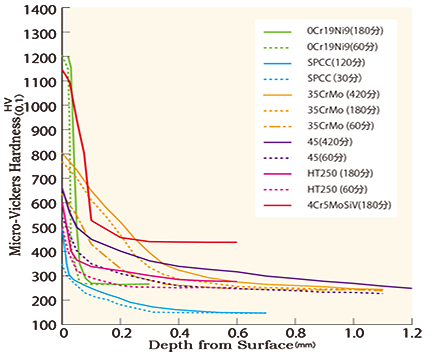

Hardness Distribution of ISONITE

Surface hardness and hardened layer depth provided by ISONITE are dependent on material. It can also process SUS and cast iron materials, which are usually difficult to heat treat.

Applications Example

- Mechanical parts (clutch parts, valve, brake parts, crankshaft, differential case, pinion shaft, bearing parts, etc.)

- Other molds, etc.

Production Equipment of ISONITE

2 ISONITE Furnaces

Effective Size: Φ900 x 1350H

Shot Blasting Machine

Messages

Messages