- Gas Carburizing · Gas Carbonitriding

- It can improve the strength characteristics of various mechanical steel parts represented by automobile parts.

- Use of steel types, surface hardening steel (low carbon alloy steel), low carbon steel, stamping steel plate.

- It can obtain a very thick hardening layer, but also ensure that the internal has a very high toughness.

- The depth and surface hardness of the hardened layer can be adjusted according to the requirements.

- According to the internal hardness and the shape of parts, there are many kinds of quenching oil to choose.

- The surface is smooth and light gray (if tempered at low temperature)

- It can improve wear resistance, impact strength and fatigue strength.

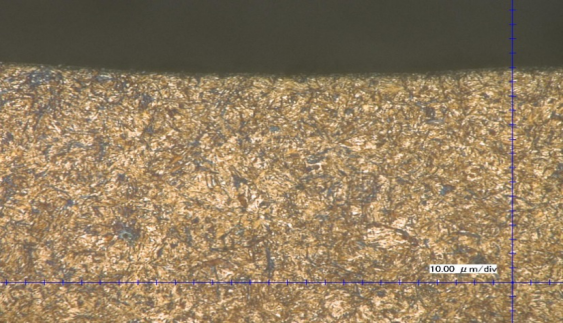

Section Model

Metal structure of carburized layer (Martensite)

- The figure shows the alloy steel (Case Hardening Steel) with carbon content of 0.2%, which is the metal structure of carburized layer during gas carburizing, quenching and tempering.

- The carburized layer forms a uniform carburized and quenched layer of about 10 ~ 15% retained austenite in the material of micro martensite.

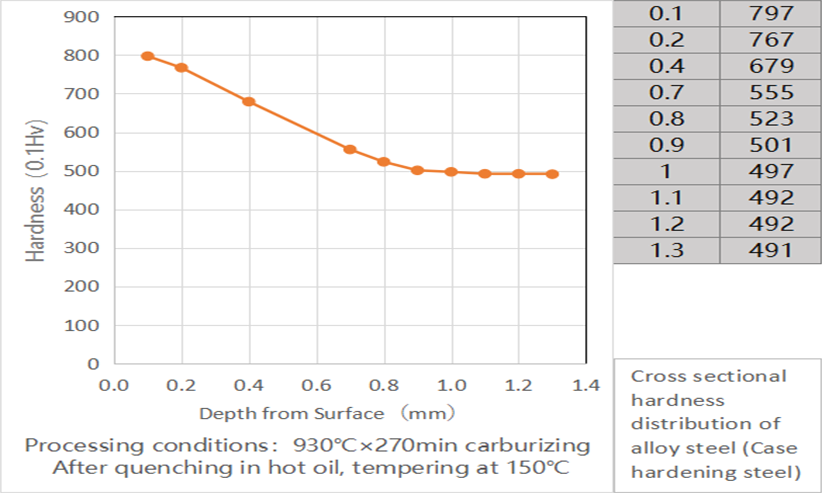

Hardness Distribution of Alloy Steel Section

It can ensure the high hardness of about 800hv near the surface layer, and the overall hardening layer depth is about 0.9mm.

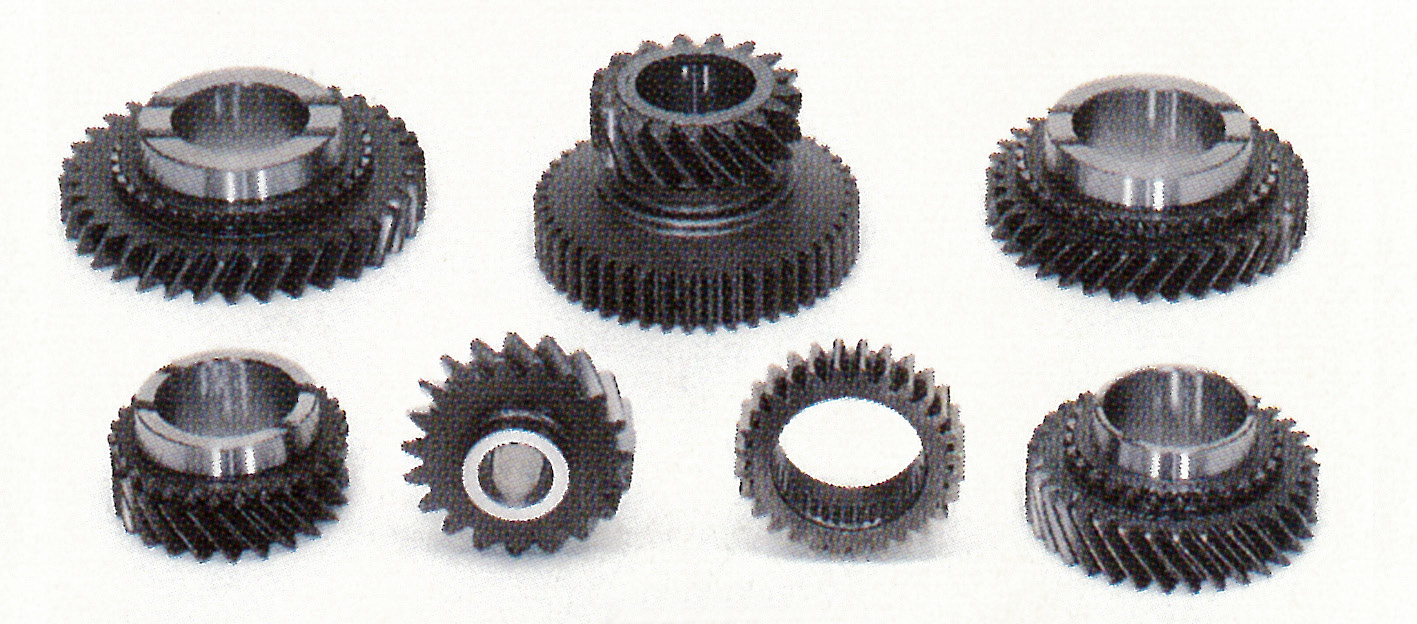

Example

- Gear

- Shaft

- Transmission

- Camshaft

- Car door latch

- Various engine parts

Production Equipment of Gas Carburizing

Gas Carburizing Furnace(Batch Type):2

Effective Size of Furnace:760W*1230L*720H

Messages

Messages